Machining

Machining workshop

Joseph Martin has a well-equipped, modern and efficient machinery. We master our manufacturing processes and guarantee a best quality production, in average and large series, from diameters 0.5mm up to 32 mm.

A steady rate of investments and a good partnership with the machine builders enable us to boost our technological lead and to maintain a high productivity level.

We modify and adapt our production means so that they meet our customers specific requirements.

Machinery :

- 42 cam-lathes (6 & 8 spindles),

- 32 CNC multi-spindles (6 & 8 spindles),

- 13 CNC single spindle,

100% automatic sorting

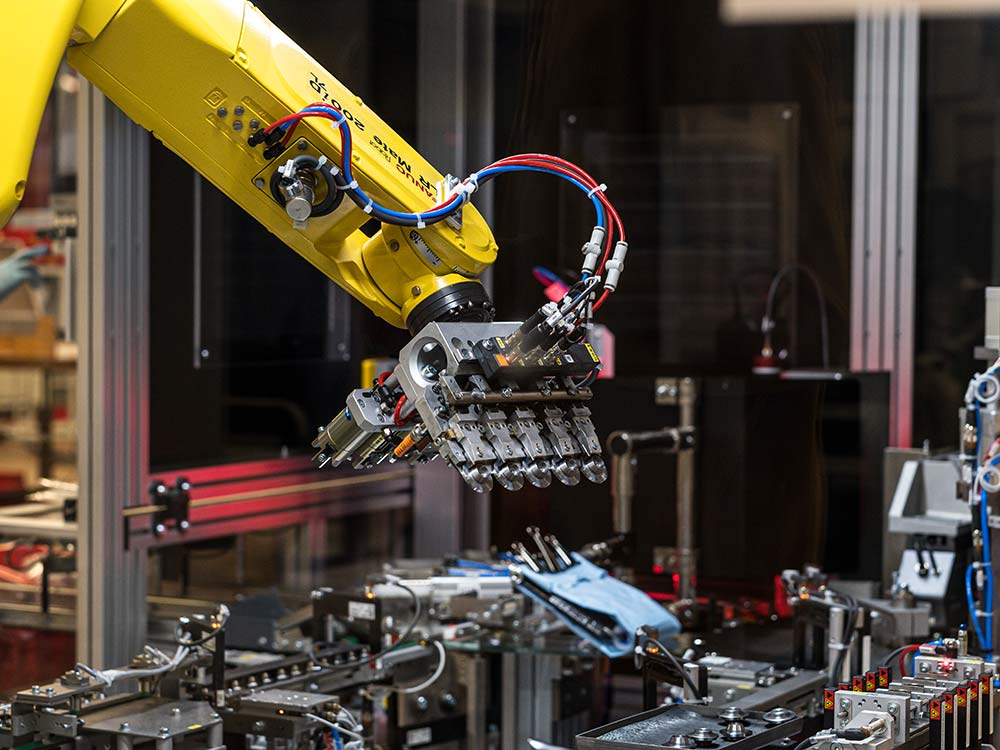

Always looking for the 0 PPM goal, we develop and invest in automatic control solutions. These may be customer dedicated or flexible machines, enabling us a continuous adaptation to your needs.

We implement following controls :

- Camera controls (aspect),

- Dimensional checks (laser, contact, camera),

- Eddy current method,

- Sealing and leakage tests,

- Draft control,

Assembly of machined parts

To meet your various technical requirements, our range of assembly machines (crimping, press-fitting and forces monitoring) enables us to supply you with a complete sub-assembly.

Our equipment is equipped with an automatic feeder and real-time production monitoring.

Cleaning equipments for machined parts

Joseph MARTIN has washing means equipped with ultrasounds, efficient filtration systems< as well as an in-situ corrosion protection solution. Components are washed in bulk or carefully stored in trays.

- 10 AMSONIC washing machines (A3 solvents or soap cleaning agents)

Tribofinishing for machined parts

We have some tribofinishing machines that enable us to proceed to deburring or polishing operations.

In order to preserve the environment, we treat the released effluents through our filtration base.

- 10 tribofinishing machines

Other operation

Joseph MARTIN adapts to your needs by also offering operations such as laser welding, face grinding, honing, secondary operations on raw/blank parts…

- 16 CNC-lathes with automatic feeding,

- 4 face grinding machines,

- 4 multi-spindles with robotic feeding,

- 2 KADIA grinding machines with robotic feeding,

A NEED, A QUESTION? OUR EXPERTS ARE AT YOUR DISPOSAL!