Precision Parts and Sub-Assemblies for Aerospace and Defense

We put our expertise at the service of the demanding aerospace and defense industries. We manufacture precision-machined parts in very small to medium sizes, compliant with the highest standards of quality, traceability, and safety.

Our state-of-the-art equipment and recognized know-how in France and worldwide allow us to produce complex, high-value-added components. From prototypes to large-scale production, our customers benefit from micrometric precision, guaranteed repeatability, and full control of the industrial process.

Our historic expertise in fluid control is fully applied to aerospace applications, including injection systems, hydraulics, and braking systems.

With a strong focus on performance, innovation, and continuous improvement, our flexible and responsive SME positions itself as a reliable partner for your aerospace projects.

Examples of Aerospace & Defense Applications

- Flight control system components: precision-machined shafts, bushings, rod ends, and bearings ensuring the reliability of flight commands (control surfaces, ailerons, flaps) on both civil and military aircraft.

- <>Landing gear elements: critical parts such as locking pins, spacers, sleeves, or guiding components, manufactured in high-performance alloys to withstand extreme dynamic loads.

- Hydraulic and pneumatic system parts: valves, fittings, check valves, and manifold bodies machined to tight tolerances, essential for braking systems, hatch opening, or weapon deployment.

- Structural and chassis components: inserts, fasteners, bearings, and supports made from aerospace-grade aluminum or titanium, integrated into fuselages, nacelles, or armored vehicle structures.

- Suspension and tactical damping devices: dedicated components for active suspension systems in armored vehicles or retractable landing gears, ensuring strength, robustness, and long-term durability.

Engineering and Industrialization for Aerospace

From the study and quotation stage, our teams carry out feasibility analyses and technical reviews to anticipate risks linked to the industrialization of your aerospace parts.

Thanks to our precise processes, modern equipment, in-house design office, and expertise in assembly and traceability, we deliver reliable, competitive, and compliant parts and sub-assemblies.

We place a strong emphasis on meeting delivery deadlines while ensuring long-term cost competitiveness. Our multidisciplinary teams work closely together to guarantee smooth and controlled ramp-up. Constant technological monitoring allows us to adapt our methods to the latest industry requirements.

Need a partner for machining your aeronautical parts? Contact our teams!

Aerospace assembly and sub-assemblies

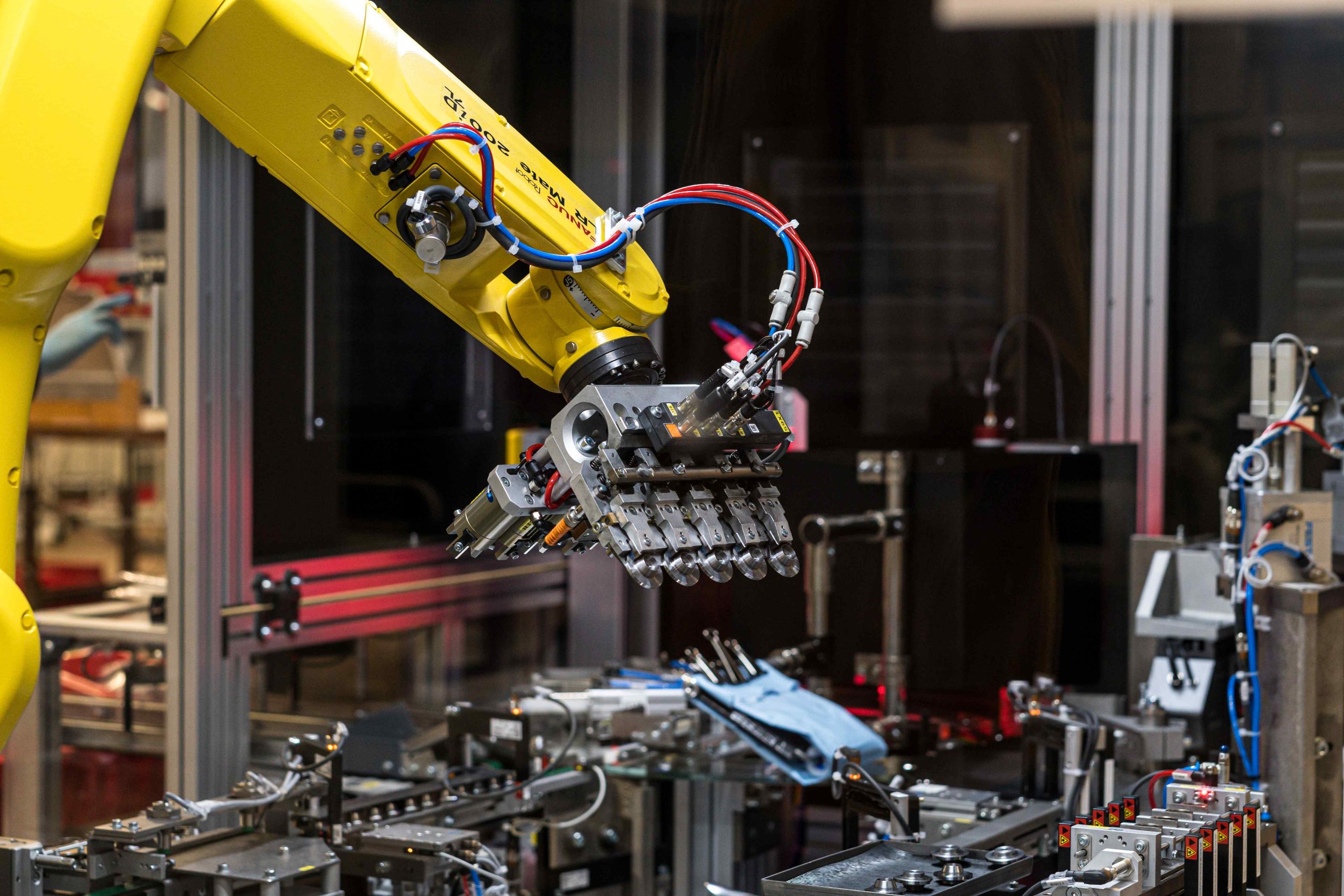

Beyond machining, we provide assembly of sub-assemblies integrating multiple components. With extensive experience across diverse projects, we offer crimping, press-fitting, torque, force, and stroke control.

We collaborate with a trusted network of suppliers (forging, stamping, surface treatment, etc.), prioritizing short supply chains and long-term partnerships. Our technical expertise enables us to coordinate all stakeholders and manage subcontracting, reducing the number of interfaces for our customers.

Traceability and compliance : a certified environment

Full production traceability is guaranteed, from raw material reception to final delivery. Each operation is recorded and secured in a robust IT system.

Our quality approach, already certified ISO 9001, is fully aligned with EN 9100 standards (certification in progress – expected 2025), ensuring compliance with aerospace and defense industry requirements.

We are also ISO 14001 certified, with an environmental commitment that includes waste reduction and the use of energy-efficient solutions.

Choosing Joseph Martin means securing a certified, competitive, and flexible partner capable of supporting your aerospace projects from design to series production – in France and worldwide.