Our experts support you. An experienced team at the service of our collaborators for sampling measurements in production

Automatic control

Automatic control solutions for turned parts

In order to move towards 0 PPM, we develop or invest in automatic control solutions. These can be dedicated or flexible allowing us to adapt to your needs.

We implement the following controls:

- Camera controls (appearance),

- Dimensional checks (by laser contact, camera),

- Eddy current

- Tightness checks and leak tests

- Effort controls

In order to always have the most efficient vision tools, our R&D team seeks the latest generation solutions.

We have a service capable of carrying out 100% of the design phase through to the construction phase of our special machines.

A NEED, A QUESTION? OUR EXPERTS ARE AT YOUR DISPOSAL!

Metrology

Dimensional inspection of machined parts

The diversity of our metrology labs enables us to measure a wide range of dimensional characteristics through “traditional” and automatic means. Control tools are present in our workshops to manage the production as best as possible.

- 3 CMM machines,

- 3 contourograph,

- 6 roughness measurement devices,

- 1 Fisherscope X-RAY measurement machine (for thickness of surface treatments),

- 2 Eddy Current devices,

- 5 machines for dimensional camera control,

- 1 CS5000 NC profile and roughness machine,

- 3 Roundtest shape defect measurement devices,

- 1 coercive field measurement device,

A NEED, A QUESTION? OUR EXPERTS ARE AT YOUR DISPOSAL!

Control

Quality control of turned parts

We check and analyze our parts according to your requirements at different steps of the process, from the receipt of the raw material to their shipment.

- 3 devices for hardness and micro-hardness measurements,

- 1 X-ray machine (for material composition),

- 2 surface treatment thickness measurement machines (Fischer Isoscope),

Our experts are at your side. An experienced team at your service for production sampling measurements.

A NEED, A QUESTION? OUR EXPERTS ARE AT YOUR DISPOSAL!

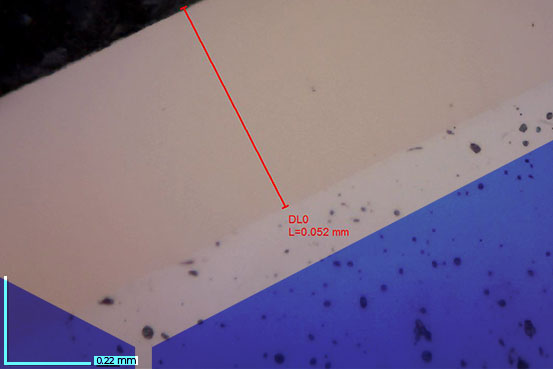

Cleanliness lab

Dimensional inspection of machined parts

Since 1997, cleanliness of industrial parts has been one of our priorities: we have been among the first companies investing in a laboratory of particle measurements This device enables us to meet our customers’ specifications according to international cleanliness standards.

- 1 PALL particles extraction bench,

- 1 OLYMPUS automatic particles measurement and counting microscope,

A NEED, A QUESTION? OUR EXPERTS ARE AT YOUR DISPOSAL!