Industrialization

Personalized follow-up to meet your expectations

Each new machined part is followed up by a project manager that drives the different steps according to customers specific requirements.

From prototypes to serial production, we optimize and make our manufacturing processes more reliable, thanks to rigorous APQP phases management.

At Joseph Martin, we design and produce in-house the needed tools and equipment required for the production of parts and sub-assemblies. Our tooling and mechanics workshops are equipped with the latest CNC machine technologies. These allow us to master the production and assembly processes.

All this is possible thanks to:

- 4 electro erosion by wire machines

- 2 CNC shaping grinders

- 1 5-axis grinding center

- 2 EWAG universal grinders

We are developing in-house automatic control solutions, adapted to different markets. Our customers cleanliness requirements are integrated at the very first component’s study.

A need, a question? Our experts are at your disposal!

Co-design

Consulting and industrialization studies for your turned part projects

We provide our know-how and experience in order to offer relevant economic and technical solutions.

We support our customers in the design of their products:

- Materials choice

- Proposal of the most suitable heat treatment or surface treatment

- Definition of subsets

A need, a question? Our experts are at your disposal!

Design office

Make your ideas a reality with our innovating design office and reach technical excellence

The company positions itself as an overall service provider to offer a turnkey solution to our customers.

A project, a need, our experts support you to develop your new projects, from the design, the study to the prototyping and industrialization of your products.

At Joseph Martin, we offer you the synergy of different technologies necessary to support you in your projects.

Our expertise in the field of machining for more than 75 years allows us to support you and offer you reliable and economical solutions

A need, a question? Our experts are at your disposal!

Internal design

An autonomous and reactive team able to adapt our machinery to your requirements

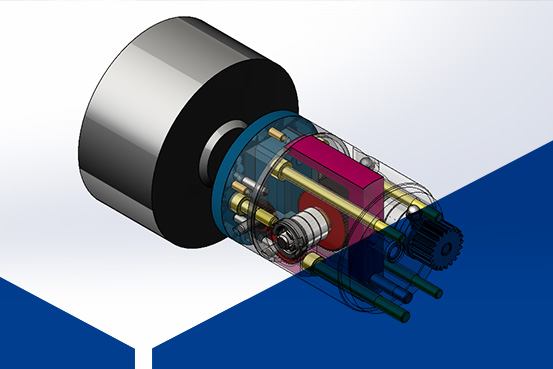

We design and produce our own equipment adapted to the manufacture of parts and sub-assemblies:

- Specific tool holders

- Hydraulic, pneumatic or CNC devices

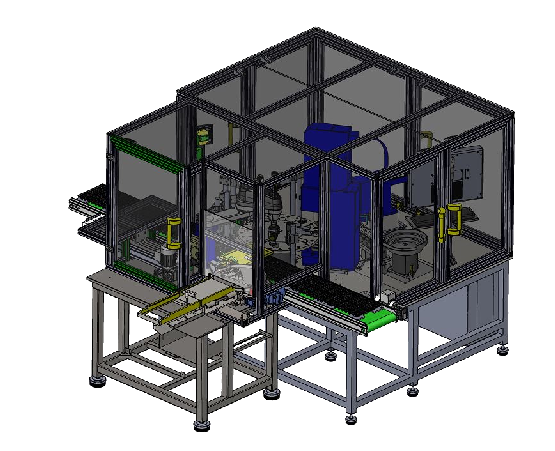

- Integration of complete machining solutions with automatic feeding and integrated control

- Automatic assembly lines integrating online controls

- 100% automatic control carousels integrating the different controls (dimensional, functional and aspect)

A tailor-made answer to your needs. Know-how and expertise for our customers.

A need, a question? Our experts are at your disposal!