Precision Machining for Trucks and Industrial Vehicles

We support leading truck manufacturers and European OEMs in the precision machining of mechanical parts.

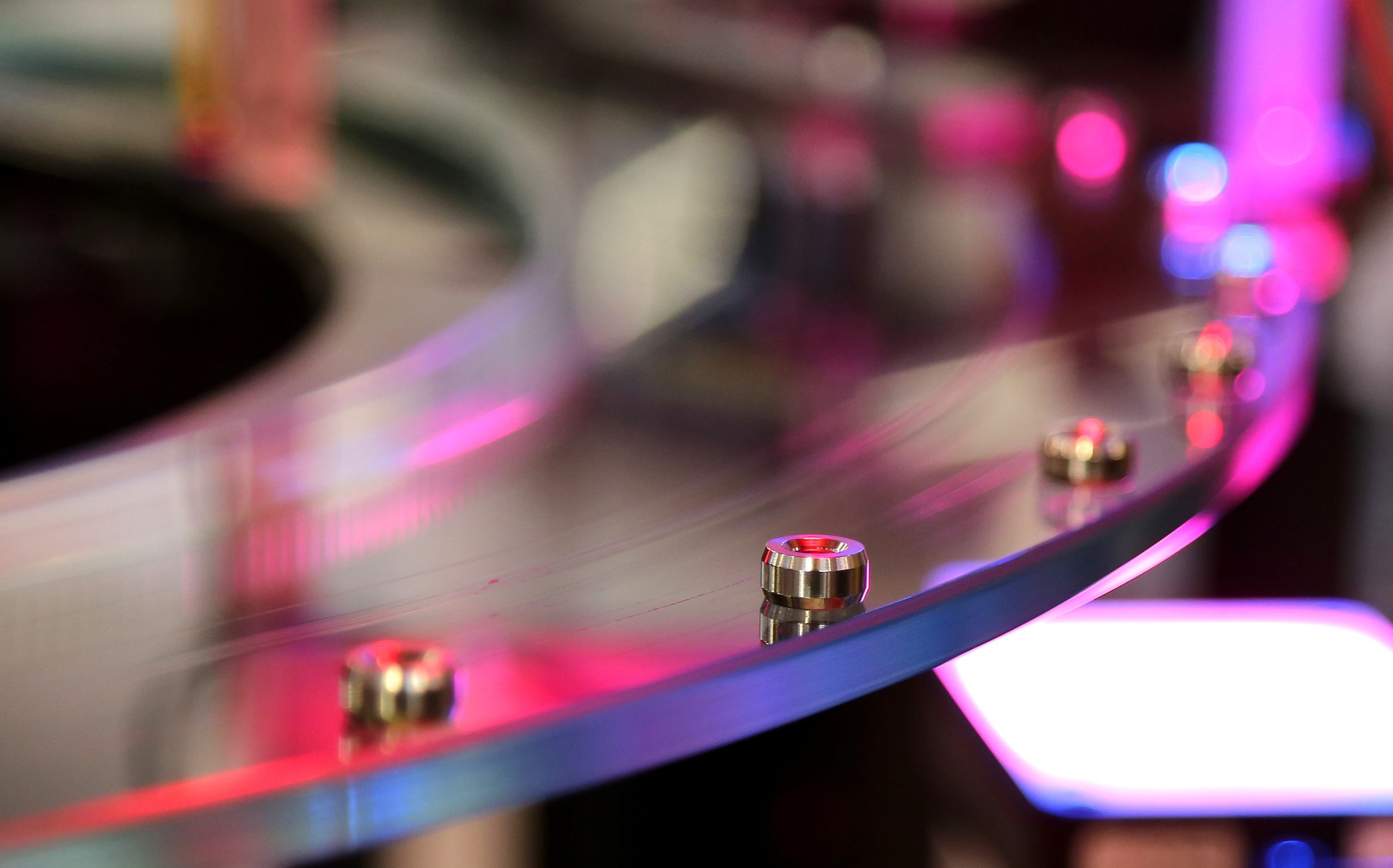

Specialized in bar turning and machining diameters from 0.5 to 32 mm, we produce in all series sizes thanks to the combination of traditional multi-spindle technology and modern CNC machining.

Our recognized expertise in the automotive industry, combined with the flexibility of a family-owned SME, allows us to deliver competitive and cost-efficient solutions while maintaining the highest levels of quality and reliability.

Applications for Trucks, Buses, and Industrial Vehicles

- Emission reduction systems: tubes, housings, nozzles, shafts, and seals designed for heavy-duty engines to meet the latest environmental standards.

- Alternative powertrains: machined parts for hydrogen systems, supporting the energy transition and vehicle autonomy.

- Transmission and fluid systems: shafts, valves, and hydraulic or regulation components machined to tight tolerances for optimum performance.

- Braking systems: control shafts, pistons, and machined parts in special steels or aluminum for pneumatic and hydraulic brakes, ensuring safety and reliability.

- Suspension systems: precision-machined rod ends, bushings, spacers, and supports providing ride comfort and road stability for heavy vehicles.

Certified Quality and Reliability

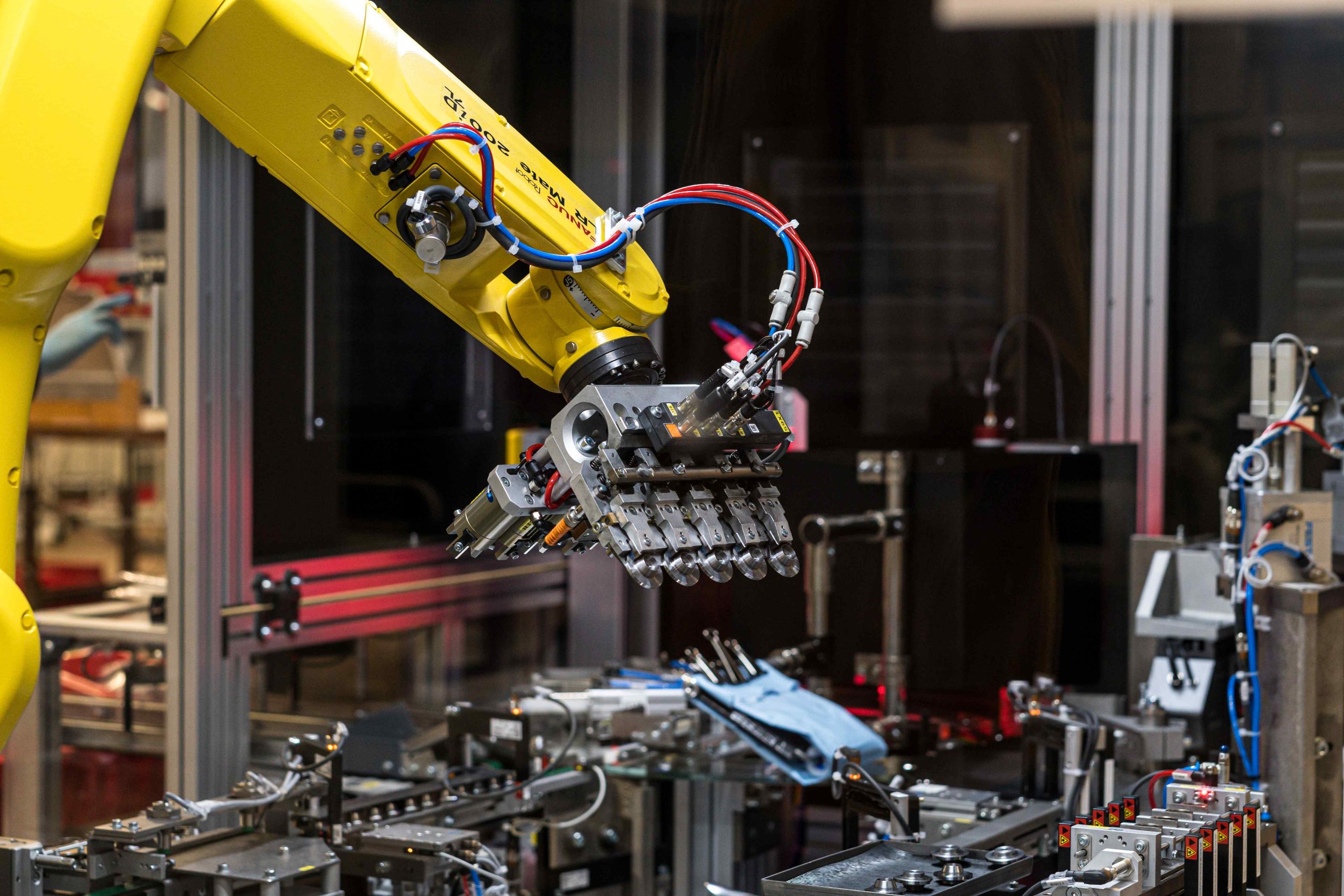

Our high-performance machine park (CNC multi-spindle lathes, single-spindle CNC machines, automated lines) ensures precision, responsiveness, and high production rates.

Integrated quality controls include 100% sorting, camera inspection, laser measurement, eddy current testing, and torque or leak tests — all targeting zero defects (~2 ppm).

Full production traceability is guaranteed through an advanced IT system within an environment certified to ISO 9001, ISO 14001, and IATF 16949 standards.

Need a partner for machining your truck parts? Contact our teams!

Engineering and Custom Industrialization

From the design phase, our design office supports you with:

- Material selection adapted to your needs (steel, stainless steel, aluminum, composites)

- Feasibility studies

- Custom tooling design

- Prototyping through to full-scale industrialization

Your projects are planned according to APQP methods, with a controlled ramp-up process.

With experience in the long production cycles typical of the truck sector, we ensure secure planning and strict milestone compliance — from industrialization to series delivery.

Assembly and Finishing Operations

We also integrate assembly operations (crimping, press-fitting, torque/force/stroke control) as well as finishing processes such as sorting, ultrasonic washing, vibratory finishing, laser welding, grinding, or lapping.

Your parts are ready-to-use upon delivery, meeting the most demanding technical and quality requirements.

CSR Commitment and Sustainable Performance

Our CSR approach, certified to ISO 14001, is reflected in concrete ecological investments — noise reduction modules, heat recovery systems, effluent treatment, and local sourcing with trusted regional partners.

We combine industrial performance and environmental responsibility to support your heavy vehicle projects sustainably.

Need a partner for machining your truck parts? Contact our teams!